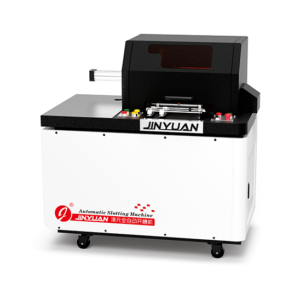

ACCUTEK AT2

Machine Capabilities

- Panasonic Full servo control system make it high speed、high precision and more stable.High quality ball screw combine with linear guideway feeding design ensure the feeding precision as well as stability.

- The casting on clamping increases the grasping force, meanwhile does not scratch the material.

- Length encoder and closed-loop control system matches the finished product with the source file perfectly.

- The mono-bloc casting of bending mechanism has high molding degree With 40L/ Mini Oil-free Air Compressor.

- Standard adjustable lift feeding cabinet can satisfy all sizes of material.

描述

Machine Detail

Machine Specification

| Feeding System | Circulation-typed clamp feeding system |

| Slotting System | Grinder cutter and Milling cutter double drives slotting system |

| Bending System | Double blade alternate bending system |

| Suitable Material | Stainless Steel、Galvanized Steel、Aluminum Plate、Aluminum Profile |

| Material Height | 20-125mm |

| Material Thickness | Stainless Steel / Galvanized Steel ≤1.2mm Aluminum Plate ≤1.2mm Aluminum Profile ≤ 1.0mm |

| Size Accuracy | ±0.1mm |

| Input File Format | .dxf |

| Dimensions | Machine L1325*W770*H1503MM Feed Tank L552*W590*H1150MM |

| Power | AC 220V 50HZ 3.0KW |

| Air Source | 0.6m³/MIN |

| Total Weight | 500KGS |