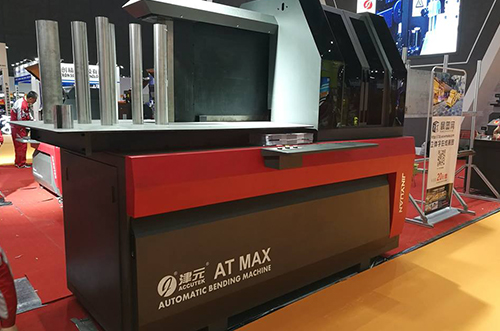

ACCUTEK AT MAX

Applicable Material

Stainless steel、Galvanized Steel

Model Interpretation

- Square letter and outdoor advertising letter

- Progressive clamp feeding system

- Single planer cutter slotting system

- The thickened double blade alternate bending system

- Japan imports Panasonic servo control system

Key Advantages

- Double blade alternate bending system, special designed bending tools rod and tool edge structure, adoption of electric motor with high quality ball screw.It can keep bending radian of high & wide materials consistent. Professional processing thick plate materials.

- The material waste can be reduced effectively because two sets of clamping devices are set before and after the encoder.

- Single planer slotting system using CNC lathe tool as a slotting tool. Plane knife utilizes hard alloy knife imported from German for durability and high precision.High power servo drive is equipped with high quality ball screw and linear guide rail to ensure smooth and flattened.

描述

Machine Detail

Machine Specification

| Feeding System | Progressive-typed clamp feeding system |

| Slotting System | Single planer slotting system |

| Bending System | Double blade alternate bending system |

Materials Specification

| Material Height | 20-645MM |

| Material Thickness | 1.5MM MAX |

| Size Accuracy | ±0.1MM |

| Input File Format | .dxf |

| Computer | XP system or window7 32-bit system with a PCI card slot to install the control card. |

| Power | AC220V 50HZ 4.0KW |

| Air Supply | 0.6m³/ MIN |

| Dimensions | Machine L2800*W1219*H2445MM |

| Total Weight | 1500KG |