ACCUTEK AT1 PLUS

Applicable Material

Stainless steel、Galvanized Steel、 Flat Aluminum、Aluminum Profile

Model Interpretation

- Progressive clamp feeding system

- Double blade alternate bending system

- Planer cutter and alloy rotary swing milling cutter automatic slotting system

- Slotting Angle: the smallest slot Angle 60 ° the max slotting Angle 120 °

- Panasonic servo control system

Key Advantages

- Double blade alternate bending system, special designed bending tools rod and tool edge structure, capable of processing with plate and profile. Better choice for small angle and radian bending.

- Double-cutter slotting, using planer cutter for Stainless steel and Galvanized sheet, using big alloy rotary swing arm milling cutter milling cutter for Aluminum plate and Aluminum profiles.There is no need to readjust the replacement material.

- Can be slotted at any angle to avoid the conflict of groove wall when making sharp angle.

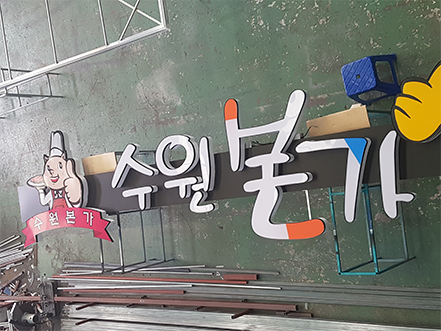

描述

Machine Detail

Machine Specification

| Feeding System | Circulation-typed clamp feeding system |

| Slotting System | Double cutters slotting system/plane and milling cutter |

| Bending System | Double blade alternate bending system |

Materials Specification

| Material Height | 20-125mm |

| Material Thickness | Stainless steel/Galvanized Steel/Flat Aluminum1.2MM MAX Aluminum Profile 1.0MM MAX |

| Size Accuracy | ±0.1mm |

| Input File Format | .dxf |

| Computer | XP system or window7 32-bit system with a PCI card slot to install the control card. |

| Power | AC220V 50HZ 3.0KW |

| Air Supply | 0.6m³/ MIN |

| Demensions | Machine L1729*W1000*H1717MM Feed Tank L550*W597*H1150MM |

| Total Weight | 600KG |